3 Major Differences Between M8 and M12 Connectors

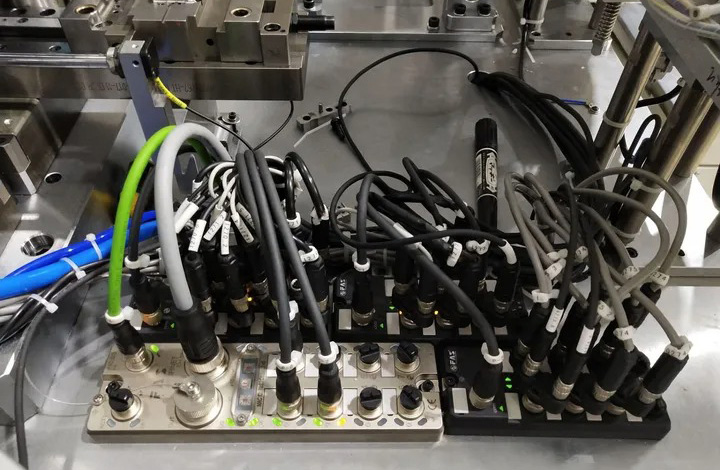

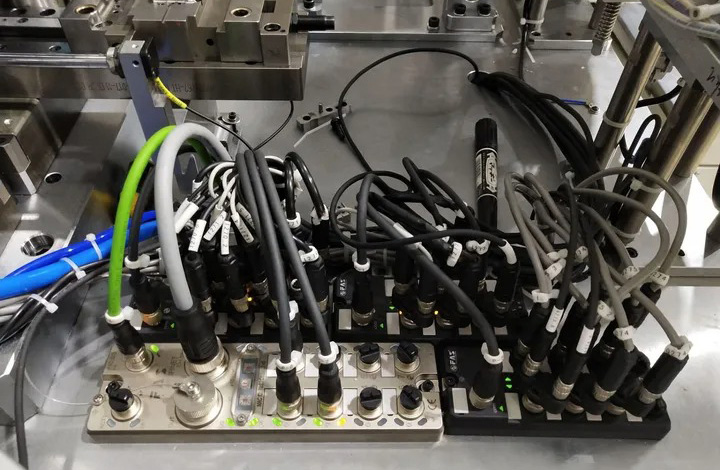

M8 and M12 connectors are widely used in industrial automation and machinery. They can transfer power, signals and data and are therefore essential in ensuring the reliability of communication and control systems.

M8 connectors have M8*1 thread, threaded connections, and IP67 protection rating and are typically available in 3, 4, 5, 6 and 8 pin. M8 connector cables are available in PVC (plain) or PUR (oil and abrasion-resistant) materials. M8 connectors are rugged and reliable, with high resistance to vibration, shock and moisture. They are often used in harsh environments where other connectors may fail. M8 connect sensors, actuators and other devices in industrial automation applications.

M12 connectors have a thread of M12*1, which is threaded to achieve IP67 protection. m12 connectors are available with and without cables. The cable can be PVC (universal) or PUR (oil resistant). The M12 connectors are widely used as connection solutions for sensors, actuators, and industrial Ethernet and fieldbus devices in harsh and corrosive industrial automation environments.

1. Physical Characteristics

- Outside Diameter Size: M8 connectors have an outside diameter of 8mm, while M12 connectors have an outer diameter of 12mm. Size difference may be evident in some applications because it will affect the amount of space occupied by the connector and the ease of operation.

- Size Differences: M12 connectors are larger than M8 connectors, M8 connectors 3-pin 4-pin 5-pin 6-pin 8-pin available; M12 connectors 2-pin 3-pin 4-pin 5-pin 6-pin 8-pin 12-pin 17-pin, M12 connectors have more pin options.

- Connector Type: Compared with M12 connectors, M8 connectors have a smaller range of physical connector types.

- Protection Level: The standard protection level of M8 connectors is IP67, while the standard protection level of M12 connectors is IP65/IP67.

2. Performance Characteristics

- Transmission Bandwidth: M12 connectors usually have a greater transmission bandwidth and can reach more than 1 Gbps. While M8 connectors are generally suitable for low-speed signal transmission, the rate is below 5 Mbps.

- Current Transmission: M12 connectors are usually suitable for high current transmission, up to 10A or more, while M8 connectors can transmit up to 4A current.

- Transmission Distance: due to the distributed nature of the M12 connector, the transmission distance is more advantageous, generally up to 100 meters or more. As M8 connectors are usually used for small internal equipment connections, the transmission distance is relatively short, typically no more than 30 meters.

3. Usage Scenario

a. For the scenario that needs to connect small devices, the M8 connector is a better choice, such as automotive, lighting, control equipment, etc. The M8 connector is small, has a long life, and is suitable for harsh environments.

b. For the need to connect large automation equipment scenarios, M12 connectors are better choices, such as industrial automation, robotics, sensors, etc. M12 connectors support high-speed data transmission and high current, higher protection level, suitable for complex environments and long-distance transmission scenarios.

c. In practice, many scenarios require one of two connectors, M8 and M12, which must be selected according to the necessary bandwidth, current, protection level, transmission distance and other factors.

d. M8 and M12 connectors may also have different environmental ratings, affecting their suitability for specific applications. An important environmental characteristic is the operating temperature range, which refers to the temperature range in which the connector can safely operate. M12 connectors tend to have a more comprehensive operating temperature range than M8 connectors, which makes them more suitable for applications in extreme temperature environments.

Factors to Consider When Choosing Between M8 and M12 Connectors

Transmission current and voltage: When selecting a connector, it needs to be matched to the current and voltage to be transmitted to ensure the efficiency and safety of the transmission.

Transmission of signal types and data volume: When selecting a connector, you need to consider the kind of signal to be transmitted and the data size to ensure that it can transmit and receive signals well. If you need to transmit a large amount of data, M12 connectors are more suitable.

Protection level: The protection level of M8 or M12 connectors must be considered according to the environment and use of the equipment to ensure integrity.

Installation space: the choice of connectors needs to consider the size of the equipment space constraints to ensure that the connector can be installed correctly in the space.

Transmission distance: Transmission distance is another important consideration when selecting a connector. If the transmission distance is short, it is recommended to choose M8 connectors, while if the transmission distance is longer, then M12 connectors should be selected.

The number of insertions and stability: the stability of the connector and the number of insertions and removals are also important considerations. m12 connectors usually have higher stability and reliability and are, therefore, suitable for applications that require frequent insertion and removal.

When selecting M8 or M12 connectors, people should consider these factors in conjunction with the specific needs and uses of the equipment to choose the right type of connector.

Conclusion

M8 and M12 are important connector types with unique advantages and functions in different application scenarios. Targeted selection of suitable connectors according to customer needs and requirements enables safe and reliable connections and improves the device's performance.

How to choose M8 or M12 connectors to achieve the best results is very important. Customers should consider the current and voltage to be transmitted, signal type and data volume, protection level requirements, installation space size restrictions, transmission distance, plugging and unplugging times, and stability when selecting a connector, and select the most suitable connector according to the final application scenario. Correct connector selection will improve the device's performance, ensure the device's safety, and reduce the risk of failure.