Overview of MIL-DTL-38999 Connector

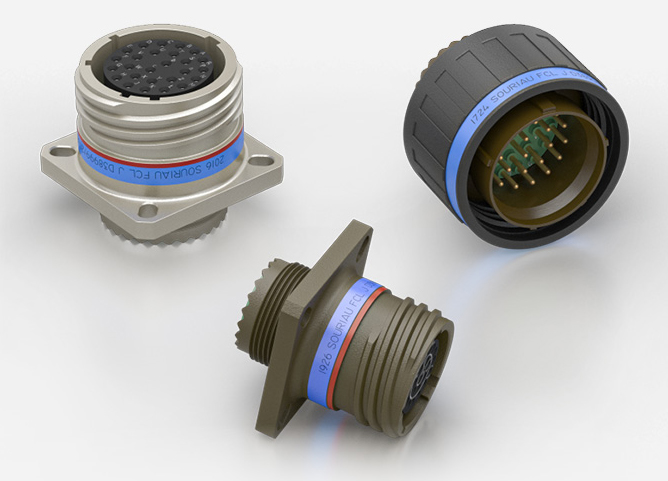

The MIL-DTL-38999 is one of the most popular and best-selling connectors available. From tactical radio units to 5G cell towers, the MIL-DTL-38999 (also known as the D-38999 or simply 38999) has become a component of choice for powering equipment and aircraft carriers across multiple industries.

Like any standard circular connector, the MIL-DTL-38999 connector establishes electrical contact to transmit power in equipment, vehicles, or similar devices that rely on electricity.

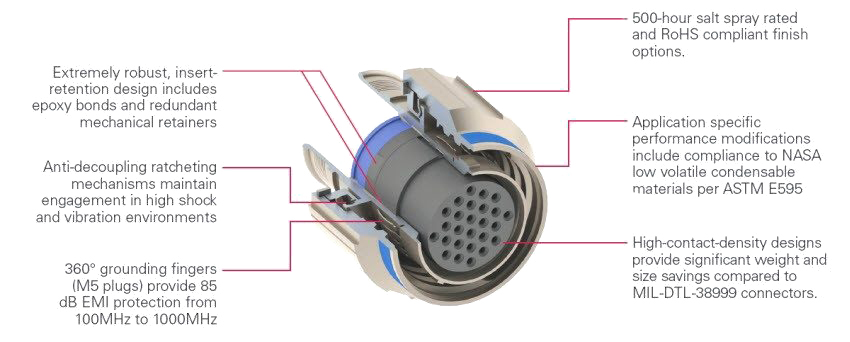

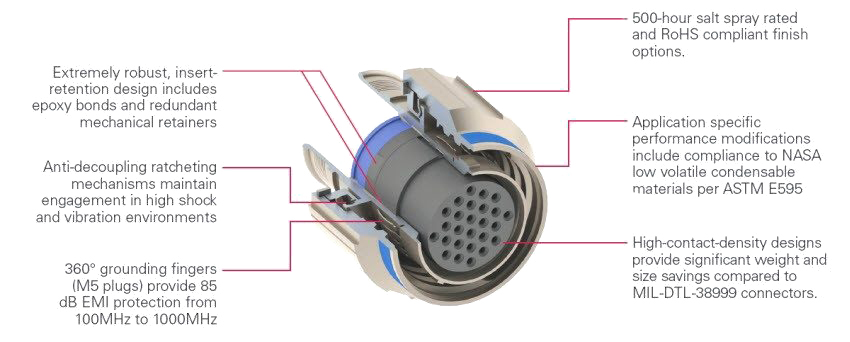

Available in aluminum, stainless steel, composite, and JVS (marine) bronze housings, the 38999 series connector is ideal for harsh environment use and is the perfect general-purpose 38999 series connector. An improved quick screw connection system, rear release crimp points, and increased vibration resistance make the 38999 series connectors the preferred choice of many users.

The MIL-DTL-38999 (formerly MIL-C-38999) circular connector is designed for various industries, notably military, aerospace, and defense applications. Its compact design, rugged metal housing, lightweight dimensions, and various pin counts allow design flexibility without compromising survivability in harsh environments.

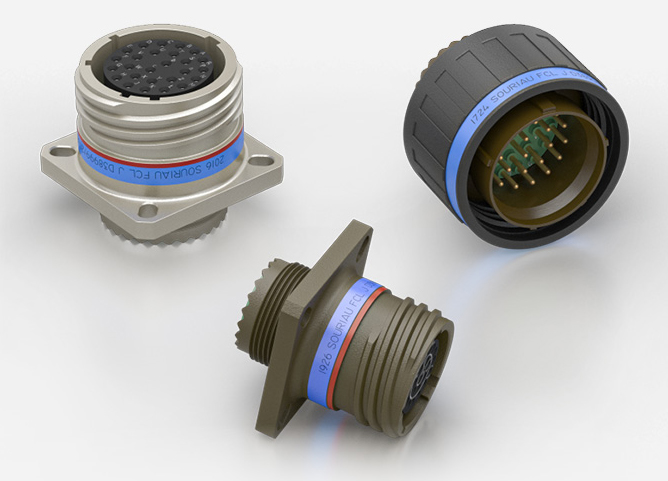

Four Series of MIL-DTL-38999 Connectors

MIL-DTL-38999 Series I connectors have a bayonet connection mechanism that performs well in moisture, wind, and high-vibration environments, with housing sizes ranging from 9 to 25 and more than 50 QPL-approved insertion methods. They were originally designed to meet the high-performance requirements of cable-to-panel applications in the military and aerospace markets.

The housings are made of aluminum alloy with four conductive coatings, black zinc-nickel, olive green cadmium, nickel or green zinc-cobalt, providing electrical continuity between paired housings before contact bonding. Shell types include square flange receptacles, straight receptacles, short square flange receptacles that do not accept backshells, square flange receptacles for rear mounting, tamper nut receptacles, and plugs with and without radio frequency interference (RFI) shielding.

MIL-DTL-38999 Series II connectors are also bayonet style connectors and include a low-profile design to accommodate weight and space constraints. Shell sizes range from 8 gauge to 24 gauge and are available in over 40 QPL-approved insertion styles. Originally designed for civil and military aerospace applications, these highly reliable connectors feature EMI shielding and excellent resistance to shock, vibration, and liquid ingress. This variant of the 38999 connectors is not shovel-proof but still functions well in environments with wind, moisture, and low vibration.

These connectors also feature aluminum housings with conductive plating options that provide electrical continuity between mating housings before contact engagement.

MIL-DTL-38999 III series connectors use a self-locking threaded connection system. They are the market's most popular military circular connectors and meet Boeing specification BACC63 and Airbus specification EN3645. They are shovel-proof and perform well in high-temperature environments, including vibration, humidity, or wind. They provide highly reliable performance in harsh environment applications with operating temperatures up to 200°C and high vibration of up to 44g for 500 plugging and unplugging cycles.

D38999 Series III connectors are available in various QPL-approved housing materials, including aluminum, stainless steel, lightweight composite, titanium, and bronze.

These high-density connectors have an insertion arrangement capable of accommodating up to 128 pins, ranging from large (size 4) to small (size 22D), feature polarization designed to ensure proper orientation of the mating section before electrical engagement, and feature EMI shielding and hermetic sealing.

MIL-DTL-38999 Series IV connectors use the Breech-Lock mechanism for connection. As with the Series III design, they are leak-proof and perform well in high-vibration environments. These connectors are ideal for blind mating applications, requiring only a 90-degree rotation to engage and disengage.

Why Use D38999?

Originally a U.S. military standard product, the MIL-DTL-38999 connector is associated by many with high quality and rugged construction. Making the 38999 a viable option for powering commercial and military equipment.

- Withstand extreme temperatures: The D38999 connector can operate in extremely high-temperature environments. The temperature range is typical -65°C to +200°C, but some models can operate at higher temperatures. The high-temperature performance of the D38999 connector is achieved through high-temperature materials such as special alloys, ceramics and high-temperature plastics.

- Withstand extreme cold: D38999 connectors can also operate in extremely cold environments. The low-temperature performance of D38999 connectors is achieved through low-temperature materials, such as low-temperature plastics and special alloys.

- Resistant to moisture: D38999 connectors can operate in wet environments. Its sealing performance effectively prevents moisture and humidity from entering the connector interior, thus protecting the electrical components and circuits in the connector. The sealing performance is achieved by using special sealing materials and sealing structures.

- Corrosion resistance: D38999 connectors can resist various corrosive media. Its surface treatment and coating technology can improve the corrosion resistance of the connector. Common surface treatments used include anodizing, chrome plating, and nickel plating.

- Protection: D38999 connectors offer various sealing options that prevent external substances such as water, dust, and chemicals from entering the connector's interior, protecting the connector and equipment.

- Versatility: D38999 connectors can be used to transmit electrical signals, power, optical signals, and other signal types and can also be selected according to the number of different plugs and sockets, layout, pin count, etc., to meet the needs of different applications.

- Compatibility: D38999 connector is an international standard for connectors, compatible with other brands of connectors, to facilitate the connection and exchange between devices.

- Safety: D38999 connectors provide reliable electrical isolation and mechanisms to prevent misinsertion and misremoval, which can ensure the safety of equipment and operators.

And more capabilities. These demanding qualities make the 38999 connectors an easy choice when selecting components for the manufacture of electromechanical equipment.

Summary

Small in size but large in capability, the component that enables today's electronic equipment to achieve optimal performance levels is MIL-DTL-38999. From being designed to power World War II aircraft to powering today's industrial necessities such as economy flights, the 38999 has rightly become electronics professionals' circular connector of choice. The continued development of this high-demand component will continue to make it the industry standard for businesses for years to come.