Overview of RF SMA Connector

What is the SMA connector?

The SMA connector is a subminiature coaxial cable connector that derives its name from the Sub-Miniature A connector. It was developed in the 1960s as an ultra-small connector interface for RF cables with a spiral coupling mechanism. Since then, many variants of the SMA series have evolved to meet the changing requirements of the RF and microwave industry.

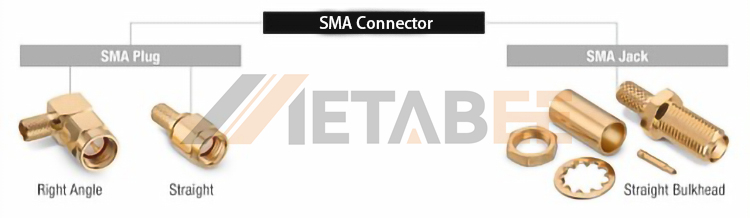

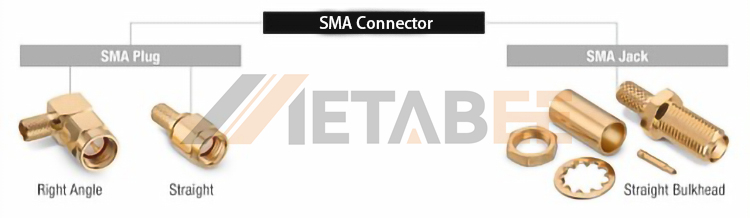

Standard Polarity

SMA male/plug connectors: In a standard SMA male connector, the center pin is surrounded by a barrel with internal threads.SMA male connectors are also known as SMA plug connectors.SMA connectors use a threaded sleeve with a diameter of 1/4 inch and 36 threads per inch.

The male connector has a hexagonal nut that measures 5/16 of an inch on opposite planes, or 0.3125 of an inch or a nominal 8mm. Therefore, we can use a wrench with a hexagonal nut. This covers the external mating connection of the male connector with the female external contact - maintaining the same inside diameter of the external conductor on the connector.

SMA female/jack connector: The center socket is surrounded by an externally threaded barrel in a standard SMA female connector. The SMA female connector is also called an SMA jack connector. The connector has a male thread length of 4.32 mm and a diameter in the threaded area of: 6.34 mm.

The dielectric supports the center pin and is made of PTFE. The PTFE centers of the two mating halves are in contact, which maintains the impedance on the connector.

To ensure that the nut on the connector is tightened, the body of the connector will not move. If it does, it can cause severe wear and shorten the life of the connector surface. It is sometimes easy to manually tighten the connector surface by rotating the body of the connector with the nut, and such behavior should be resisted.

For better tightening of nuts, a flat surface is sometimes set on the cable side of the connector assembly, allowing a second wrench to be used to prevent it from rotating and damaging the connector to the cable.

One of the keys to maintaining connector performance and life is the cleanliness of the surface. Dirt tends to accumulate and cause the contacts to become imperfect. It can also cause minor damage to the surface, which can degrade performance over time. It is recommended that loose debris be inspected and removed from the internal surfaces using compressed air or similar methods to remove dirt and dust before mating. This is critical when these connectors form part of a vector network analysis system.

Reverse Polarity

The reverse polarity SMA connector or RP-SMA is a variation of the regular SMA connector with an interface of the opposite gender. The pins and sockets are interchanged so that the male RP-SMA has a central sleeve surrounded by a female-threaded barrel, while the female RP-SMA has a central pin and a male-threaded barrel.

SMA Materials

Environmental requirements dictate the choice of materials for manufacturing connectors and surface plating. Use in harsh environments requires both the popular standard SMA connectors and customer-specific custom-designed IP68 versions.

SMA connectors typically have a brass or stainless steel body. the finish on SMA connectors is typically nickel or gold, while the stainless steel body has a passivated or gold finish. the center contacts/pins of SMA connectors are typically made of brass or gold-plated copper.

Design Notes

Mounting configurations: Primary mounting configurations include panel mount (2-hole and 4-hole flange), PCB mount, edge mount, bulkhead mount, SM, and through-hole mount.

Features 50 Ω impedance for DC (0 Hz) to 12 GHz, with variants available for operation at 18 GHz and 26.5 GHz.

SMA connector body materials are typically brass with a nickel or gold finish or stainless steel with a passivated or gold finish. Connector center contacts/pins are typically brass or gold-plated copper.

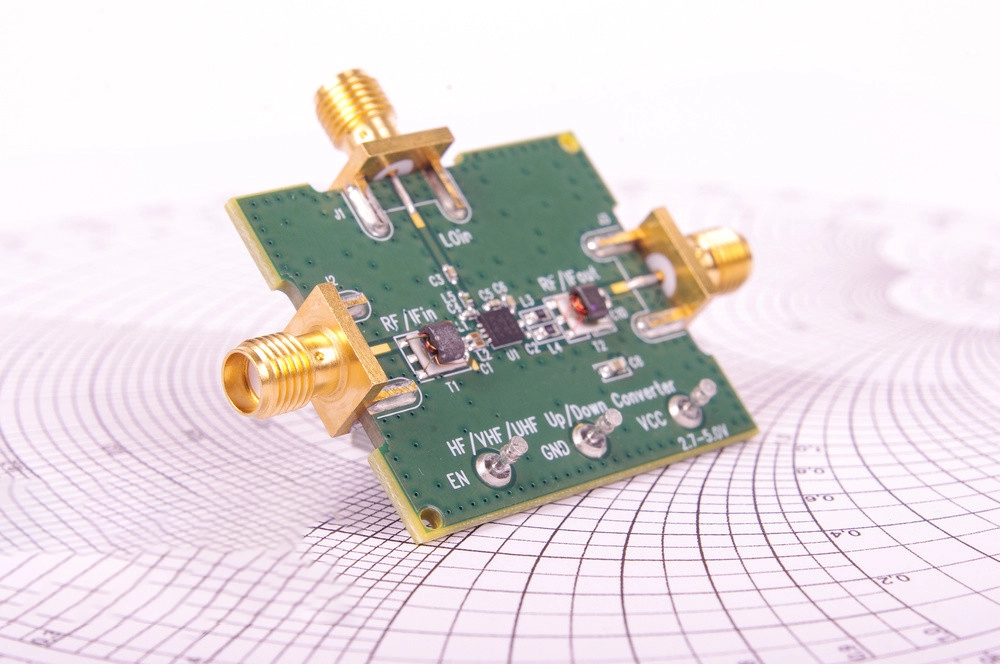

Markets, Industries, Applications SMA connectors are used in the telecommunications, medical, industrial, factory automation, and robotics markets. Applications include microwave systems, handheld radio and cell phone antennas, Wi-Fi antenna systems, and USB software-defined radio dongles and radio astronomy, especially at higher frequencies (5 GHz+).

Suppliers: SMA connectors are available from many suppliers, including TE Connectivity, Bulgin, Cinch Connectivity, COAX Connectors, Hirose Electric, I-PEX, Renhotec, JAE, Metabee, SV Microwave, and Trexon.