The Impact of FAKRA Cable Assemblies in Vehicle Signal Transmission

As the demand for intelligent driving systems and in-car entertainment systems in automobiles grows, the in-car signal transmission rate increases, leading to a gradual increase in the transmission frequency of the corresponding connecting cables.

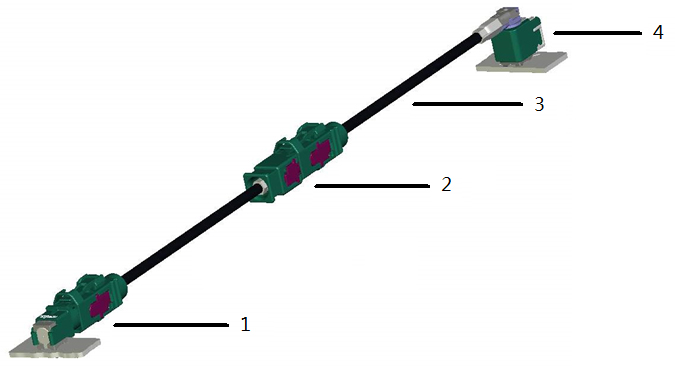

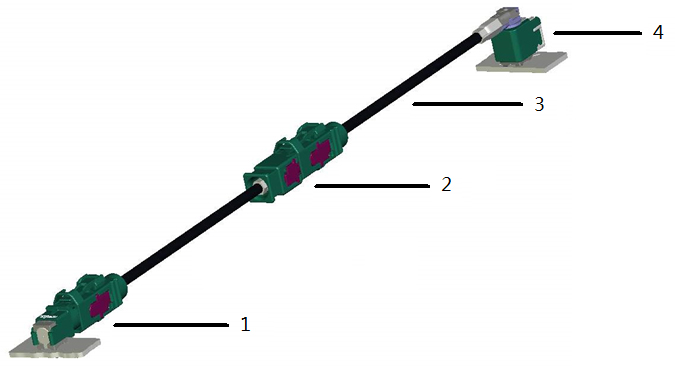

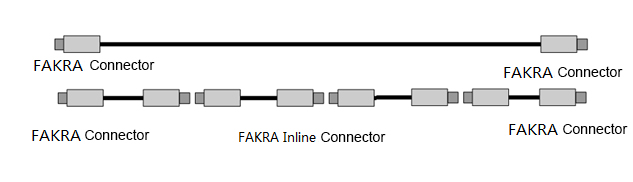

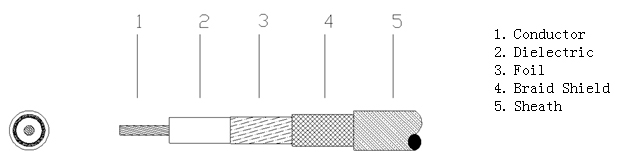

FAKRA coaxial cable is a high-speed high-frequency cable that transmits RF and HD camera signals. Mainly includes the FAKRA connector, FAKRA Inline connector, coaxial cable, and PCB board end connector.

FAKRA Coaxial Cable Connection Structure Diagram

The two important electrical properties of FAKRA coaxial cable, return loss and insertion loss, can be significantly affected in parts matching and automotive applications, resulting in degradation of the transmitted signal quality, affecting user perception, and even leading to functional failure. We mainly analyze the impact of FAKRA connectors, FAKRA Inline connectors, coaxial cables, and PCB board end connectors on the signal quality of the whole transmission link and propose engineering methods to reduce the impact.

The Impact of FAKRA Connectors on the Performance of the Entire Transmission Link

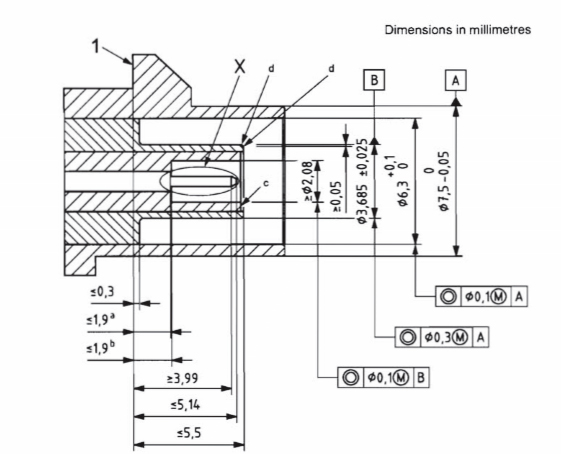

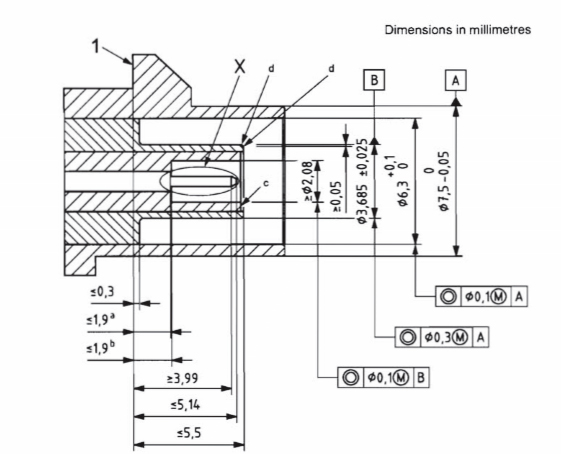

First, to understand the design standards, FAKRA connector main reference interface size standards are mainly ISO20860-1 and USCAR-18, and test standards are mainly ISO20860-2, USCAR-17, and USCAR-2. Interface size standards define the main dimensions of the FAKRA connector's axial and radial direction, including the male and female end connectors.

In the axial direction, certain dimensions are a range of dimensional tolerances, and gaps exist at the connection interface between male and female connectors after docking. Interface size tolerance caused by the gap after plugging on the electrical properties of the impact of the air gap size affects the degree of impedance matching. In addition, from the standard, the outer conductor end face at the insulating dielectric material only defines the design requirements of 50Q.

In different manufacturers' products, the insulating dielectric material is not the same phenomenon, which will also affect the effect of impedance matching. Therefore, even if the interface structure dimensions comply with the standard for different insulation materials and the interface structure of the connector, matching tests are required to verify whether the relevant electrical performance indicators are within the specified values.

Impact of FAKRA Inline Connectors on the Performance of the Entire Transmission Link

Inline connectors are inevitably used for docking throughout the harness connection and assembly process. For example, for the connection between the entertainment host and the external antenna, the entertainment host is arranged in the dashboard area, while the external antenna is at the rear of the roof, which generally needs to be connected through three sections of the instrument harness, body harness and roof harness, which will produce Inline connectors.

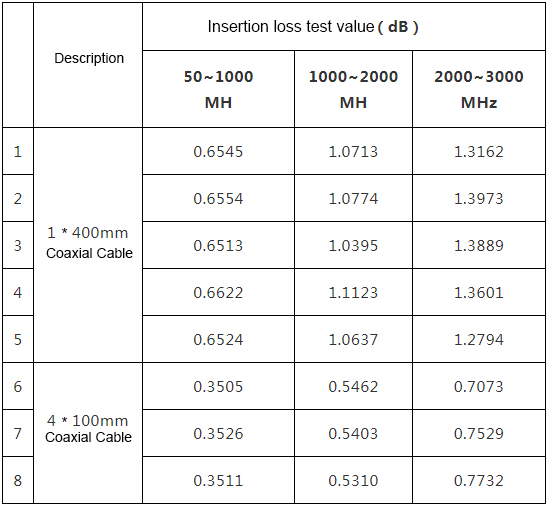

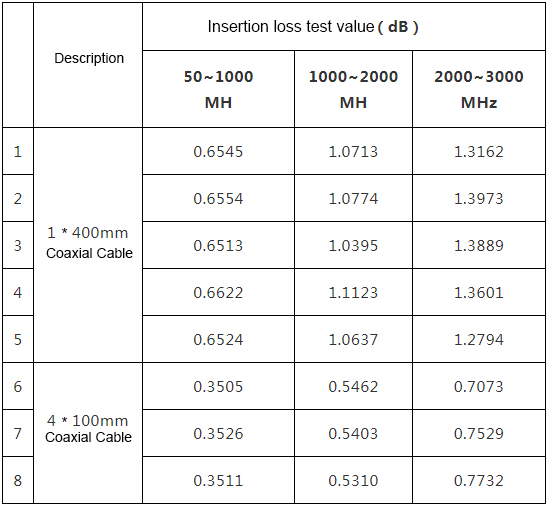

As shown in Figure 3, a connection comparison was made: one for a complete 400mm sample 1 with FAKRA connectors at both ends; the other for a 100mm sample 2 with 4 equal length segments, connected in series through 3 pairs of FAKRA Inline.

Coaxial Cable and Coaxial Cable

By comparing the insertion loss in Table 1, it can be found that the insertion loss of sample 2 is larger than that of sample 1 at the same frequency, which is due to the insertion loss of the middle 3 pairs of Inline connectors exerting an influence in the transmission link.

Insertion Loss Comparison Between Coaxial Cable and Coaxial Cable

It can be seen from Table 1 that adding Inline connectors can introduce insertion loss, from which it is known that the more the number of connectors inserted, the greater the insertion loss. At the same time, for the selected application of Inline connectors, the operating frequency needs to be considered, and the insertion loss varies at different frequencies. In practical applications, it is also necessary to verify the quality, stability, and consistency of Inline connectors.

In addition, the overall performance after the switch needs to be evaluated and tested, especially regarding Inline connections from different manufacturers. Inline connector pair mating, if an impedance mismatch occurs, will cause return loss, resulting in lower signal output power and increased insertion loss. Inline connector conductor loss, dielectric loss, and radiation energy can cause increased insertion loss, resulting in reduced signal Output power.

The Impact of FAKRA Coaxial Cables on the Performance of the Entire Transmission Link

A coaxial cable consists of two coaxial, mutually insulated cylindrical metal conductors that form the basic unit.

When considering FAKRA coaxial cables, it is usually considered that the insertion loss of a coaxial cable is equal to the sum of the losses of the connector and the cable. It should be noted that the concentricity of the pins and jacks and the contact state impact the insertion loss of the coaxial cable. "Bad contact" leads to the increased insertion loss of the coaxial cable, which may also be reflected in signal instability or direct open circuit. In addition to testing the contact resistance of the male and female connectors after insertion, we can also test the standardized contact retention force to measure and determine the contact status.

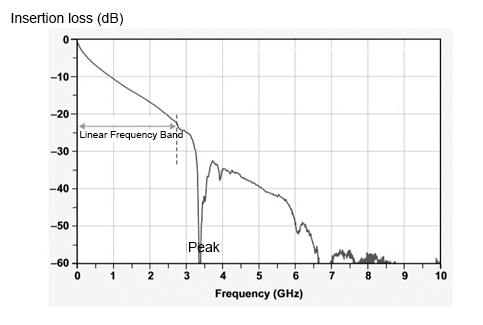

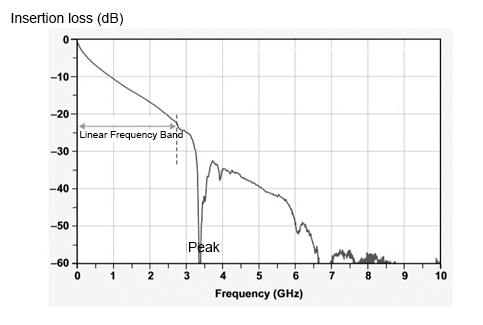

Another factor that affects the insertion loss of coaxial cables is the operating frequency range of the cable. As seen in the figure, the insertion loss test curve varies linearly within the "linear band" of the cable's operating bandwidth. In contrast, outside the bandwidth, the test results vary non-linearly and produce abrupt changes at certain frequency points, thus bringing non-negligible impact and consequences to the signal transmission of the entire link.

Sudden Change in Insertion Loss Performance Outside the Operating Bandwidth of the Cable

Impact of FAKRA Board-end Connectors on the Performance of the Entire Transmission Link

FAKRA board-end connectors compared to wire-end connectors, in addition to structural differences at the interface, the more common differences are that there are two designs of male outer conductor end faces: insulator and air. These two interfaces will have performance differences when mated with the female connector.

Another important factor affecting the performance of the male end of the board-end connector is the design of the connector at the end of the connector with the PCB board connection.

In order to achieve impedance matching, these factors affect the transmission of signals: the distance between the root of the conductor inside the board-end connector (near the insulating medium of the connector) and the PCB, the width of the signal lines on the board, the operating bandwidth of the PCB, and the size of the openings on both sides of the signal lines on the board.

When the operating frequency exceeds a certain threshold, the board-end connector, PCB board, and the corresponding welding parameters should be fully justified to avoid abrupt changes in the high-frequency signal in certain frequency bands.

Conclusion

As seen above, when selecting FAKRA coaxial cables, it is necessary to pay attention to the operating bandwidth of the cables and connectors. The operating bandwidth of each device in the full link will have an impact on the signal transmission. For connectors of different manufacturers of the same category, it is necessary to confirm the consistency of selection and matching by referring to the product's technical specifications.

The actual application of the entire vehicle cable, for the application of coaxial cable in the bending area, taking into account the transmission loss and bending durability, usually uses lower loss larger diameter of the special bending-resistant cable. Special FAKRA connectors for water and dust resistance are usually used for appliances arranged in wet areas. The arrangement in the vibration area also needs to be considered to meet the vibration needs of FAKRA connectors.

In short, FAKRA connectors, FAKRA Inline connectors, coaxial cables, and PCB board-end connectors all impact the signal transmission of the entire link. By analyzing and mastering their main influencing factors, develop appropriate design and testing measures to reduce and eliminate these effects, thus contributing to the reliability and stability of the high-frequency signal transmission.