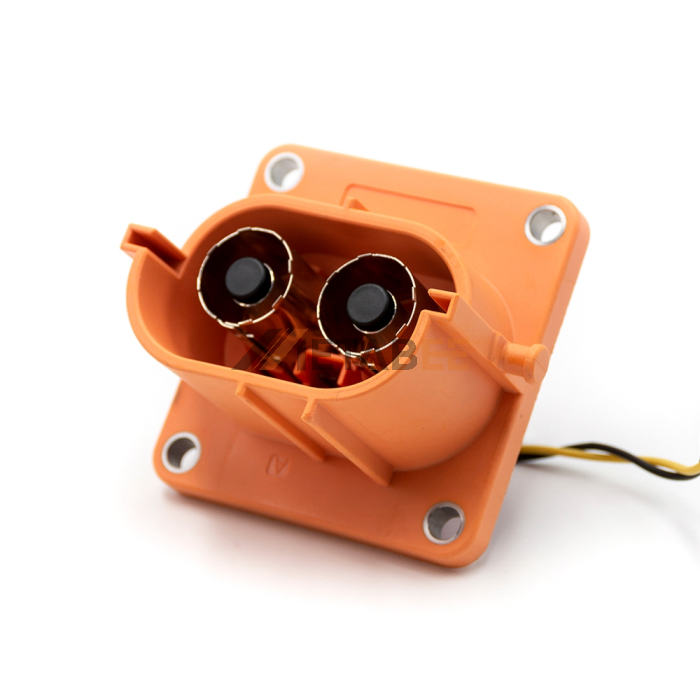

High Voltage Connector for HVIL System in EV 2 POS Socket 250A Busbar Lug A Key Box Mount

- !! This product is not compatible with other brand products. It would be best if you bought the same key plug and socket of this brand to use it properly.

-

Compact design for space considerations with EV/HEV

-

Secondary locking function

-

Suitable for a wide range of wire

-

Anti-misplacement design

-

RoHS Compliant

Descriptions

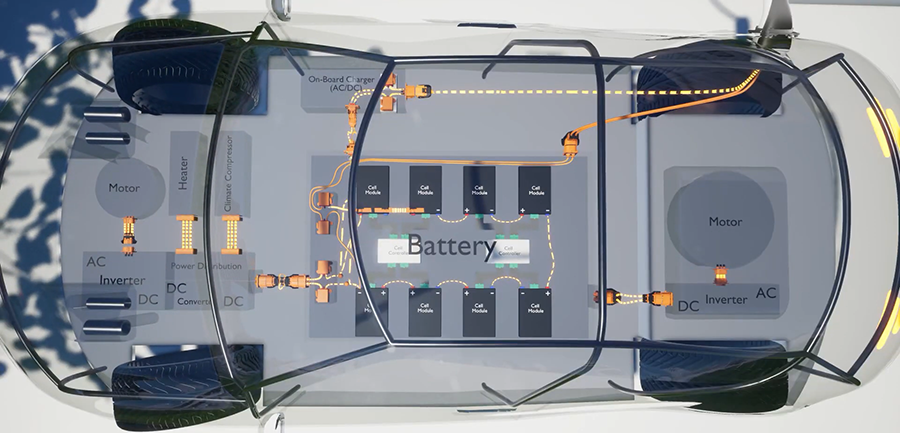

Connector for High Voltage Inter Lock (HVIL) System in EV

HVIL (High Voltage Interlock) is a safety feature that uses a low voltage circuit to monitor the integrity of the high voltage circuit, designed to protect those who may come into contact with the high voltage system of an electric vehicle.

The main electrical components in the electric vehicle (EV) high voltage interlock system are the HVIL connector and the MSD (Manual Service Disconnect) connector.

Metabee HVIL connectors family features a wide temperature and wire range and multiple keying options for many electric vehicle applications. Assembly is simplified with a lever assist for low insertion force.

Metabee HVIL connectors provide a robust design that optimizes package size and plug and header selections to create multiple wire harness assembly routing options. The touch-proof HVIL connectors and headers are engineered with 90-degree and 180-degree plugs and feature an integrated internal HVIL function and EMI shielding.

Specification

Features

Multiple Solutions for HVIL Systems in EV

SHITU offers a multiple set of automotive HVIL system solutions with high voltage connectors from 1-6 poles. SHITU’s high voltage connectors are engineered with 90-degree and 180-degree plugs and feature an integrated internal HVIL function and EMI shielding.

Safe, High-quality and Convenient

The high-voltage connectors are made of PA66 insulation and have passed a high temperature test of 128°C for 1008 hours. Assembly is simplified with a lever assist for low insertion force.

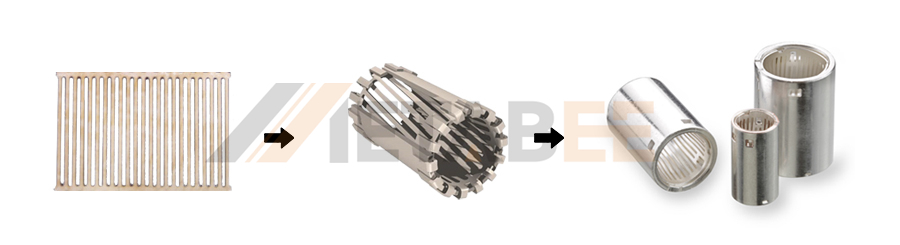

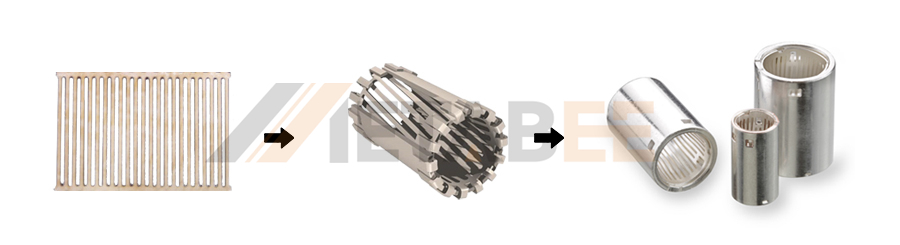

Advanced Contact Design

The core technology for any power connection system is the contact. SHITU uses advanced contacts designed to maximize power transfer while minimizing space requirements and minimizing the length and diameter required for a given current while maintaining a good temperature response.

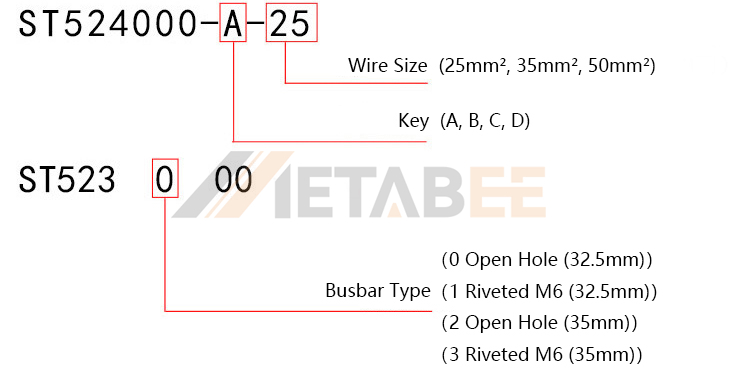

How to Order

Applications

- High Voltage Power Distribution

- Battery Pack

- Motor Controller

- Electric Air Conditioning

- Electric Heater

- Electric Power Steering

- Onboard Charger

- Defrosting

- DC/DC Converter

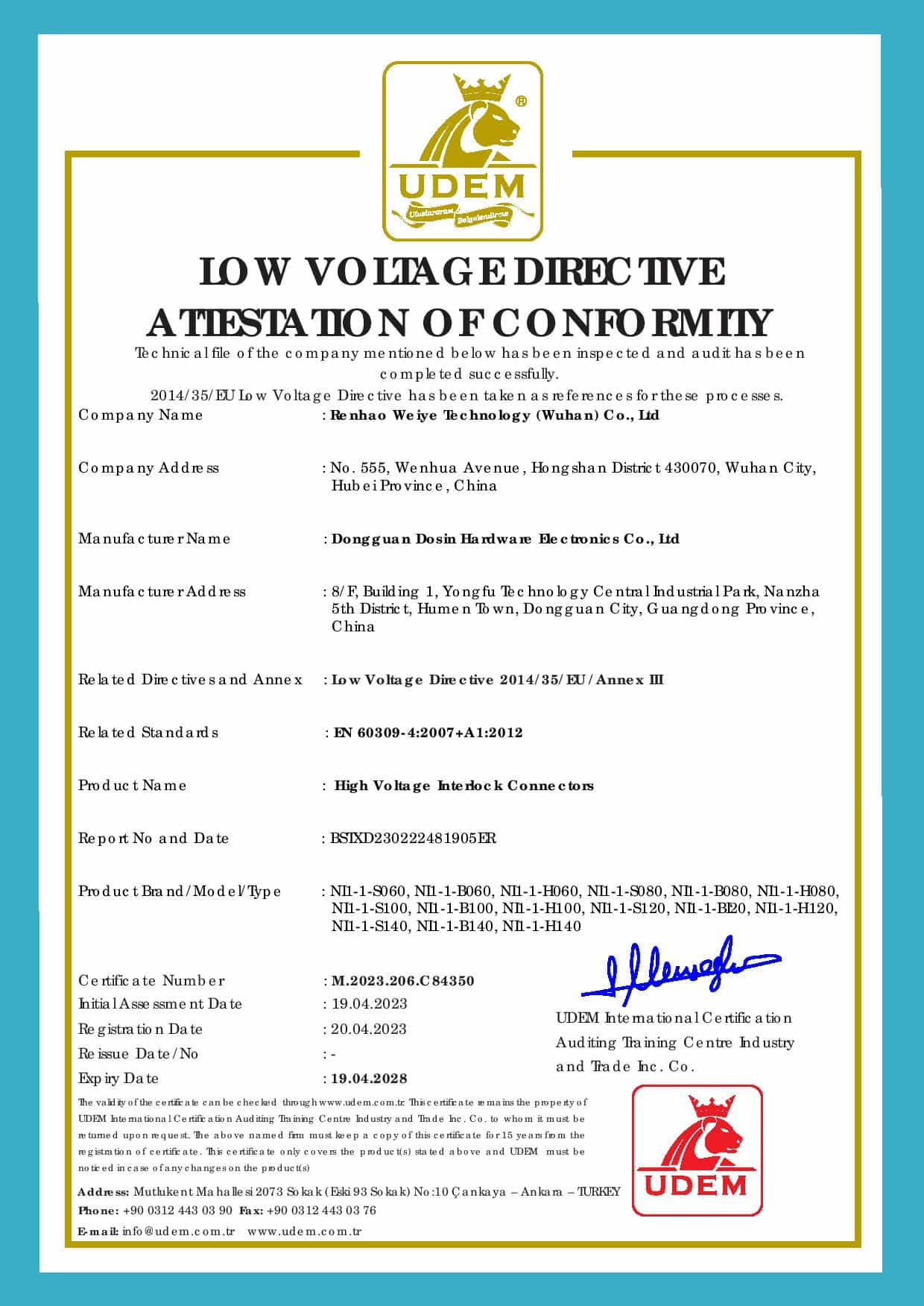

Certificates

Questions

Reviews

-

Excellent connectorThis high voltage connector has been a great addition to my EV's HVIL system. It's very easy to use and provides a secure connection every time. I also appreciate the key feature, which adds an extra layer of safety. Overall, I'm very happy with my purchase.

Posted on

-

Fast deliveryI was pleasantly surprised by how quickly this high voltage connector arrived. It was delivered in just a few days, which was much faster than I expected. The quality of the product is also top-notch. Very satisfied with my purchase!

Posted on

-

Great qualityI am very impressed with the quality of this high voltage connector. It feels very sturdy and durable, and it has been working flawlessly in my EV. The shielded cable is also a great feature. Highly recommend!

Posted on