Fakra Connectors: A Vital Component for Automobiles

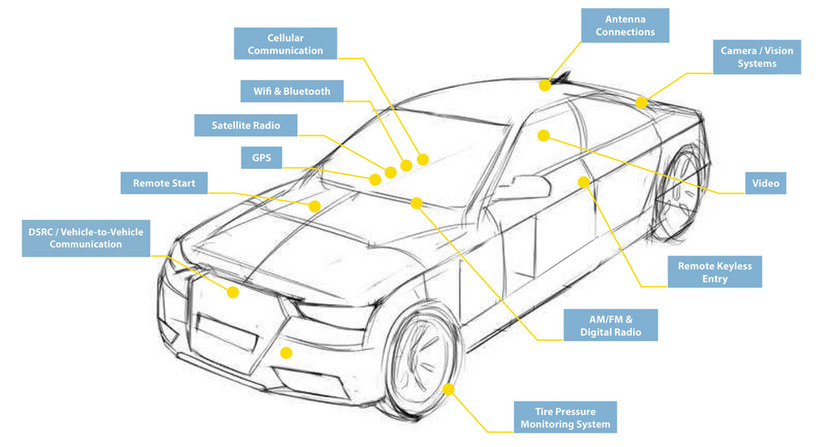

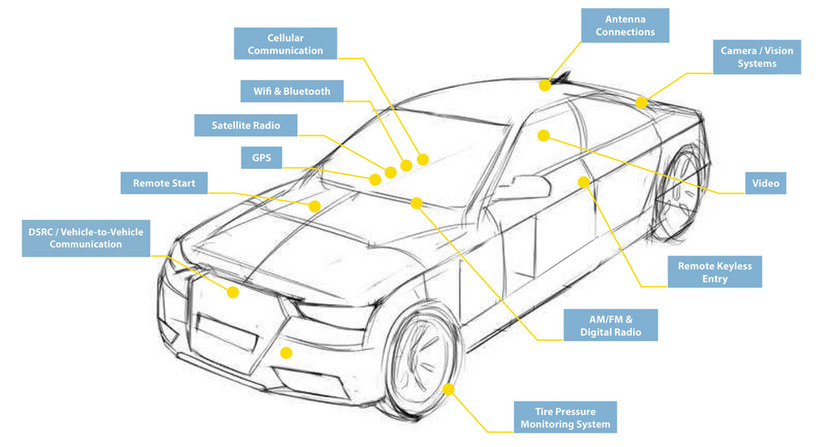

The Fakra connector is a special kind of automotive electronic connector, which is mainly used for wireless communication systems in vehicles, such as in-vehicle Bluetooth, GPS navigation, wireless network and so on. It is a high performance RF connector.

Structure of the Fakra Connectors

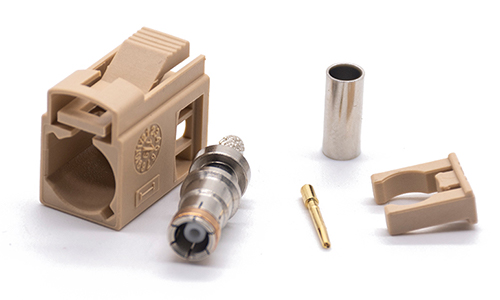

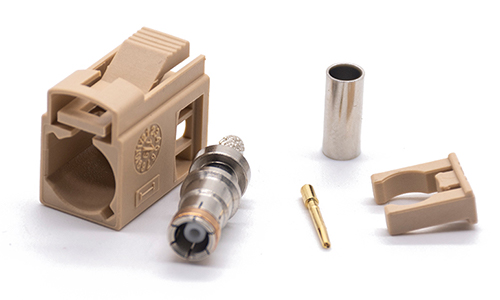

Fakra connectors are designed with a specific structure for reliable wireless signal transmission and connection. They typically consist of two main parts: a male connector and a female connector. Below are the general structure and components of a Fakra connector.

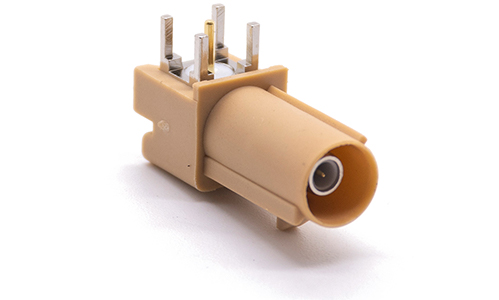

Male Connector

- Center Pin: There is a metal lead in the center section for signal transmission. It matches the center hole of the female connector.

- Outer Pins: There are multiple metal leads on the outside that are used for grounding and providing mechanical support.

- Housing: The housing is usually made of plastic material with specific colors and codes to distinguish between different frequencies and functions.

Fakra Male Connector

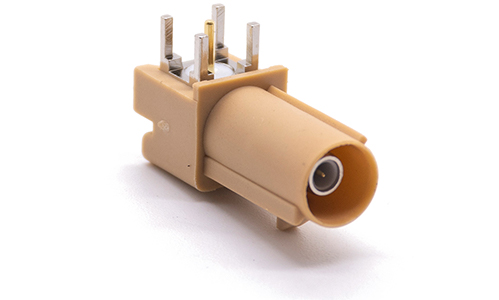

Fakra Female Connector

Female Connector

- Center Hole : There is a hole in the center that matches the center lead of the male connector. It ensures proper alignment and signal transmission.

- Outer Holes: There are multiple holes on the outside to receive the external leads of the plug and to provide mechanical support.

- Housing: The housing usually matches the shell of the plug to ensure proper insertion and connection.

The construction and components of Fakra connectors may vary depending on the specific application and vehicle manufacturer. In addition, Fakra connectors are designed to be waterproof and resistant to electromagnetic interference to suit the requirements of the automotive operating environment. They are standardized in terms of color and coding in order to correctly match and connect different wireless communication systems.

Features of the Fakra Connectors

1. Fakra connectors are used to transmit RF signals for vehicle wireless communication systems such as in-vehicle Bluetooth, GPS navigation, Wi-Fi and satellite radio. They ensure high quality signal transmission to maintain the reliability and stability of wireless communications.

2. Some types of Fakra connectors can also be used to provide a power supply. For example, in an in-vehicle Bluetooth system, Fakra connectors may be used to simultaneously transmit audio signals and provide power to Bluetooth devices.

3. The structural design provides good mechanical support and fixing to ensure the stability and durability of the connection. This is important to maintain the reliability of the connection in vehicle vibration and unstable environments.

4. Water is resistant to maintain a stable connection in the harsh operating environment of a vehicle. This is because vehicles are often exposed to rain, humidity and other liquids, so the waterproof design of Fakra connectors is critical to protecting the reliability of signal transmission.

5. Fakra connectors are designed to effectively suppress electromagnetic interference, ensuring signal purity and reliability. In automobiles, electromagnetic interference may be generated due to the presence of various electronic devices and systems. The design of Fakra connectors helps to minimize the impact of interference on wireless communication systems.

6. Fakra connectors use a number of different colors and coding to distinguish between different applications and signal types. Each color and coding corresponds to a specific frequency and function to ensure proper connection and signal transmission.

7. The use of plug-in connections makes the mounting and dismounting process easier and faster. This is very important for assembly and maintenance work on the production line.

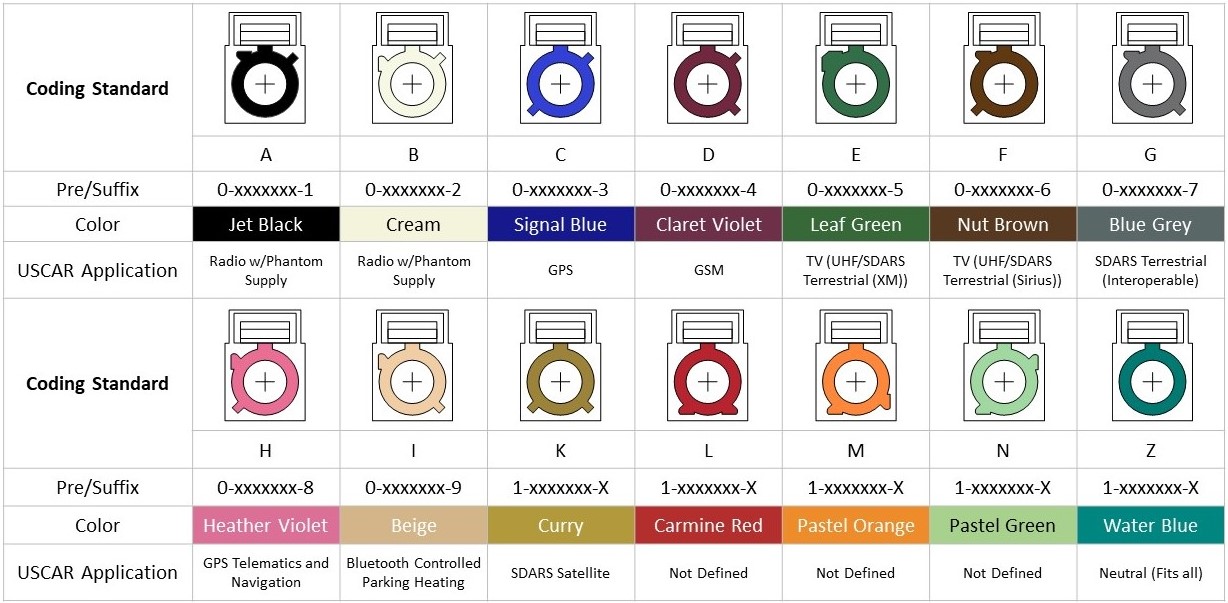

Code for Fakra Connectors

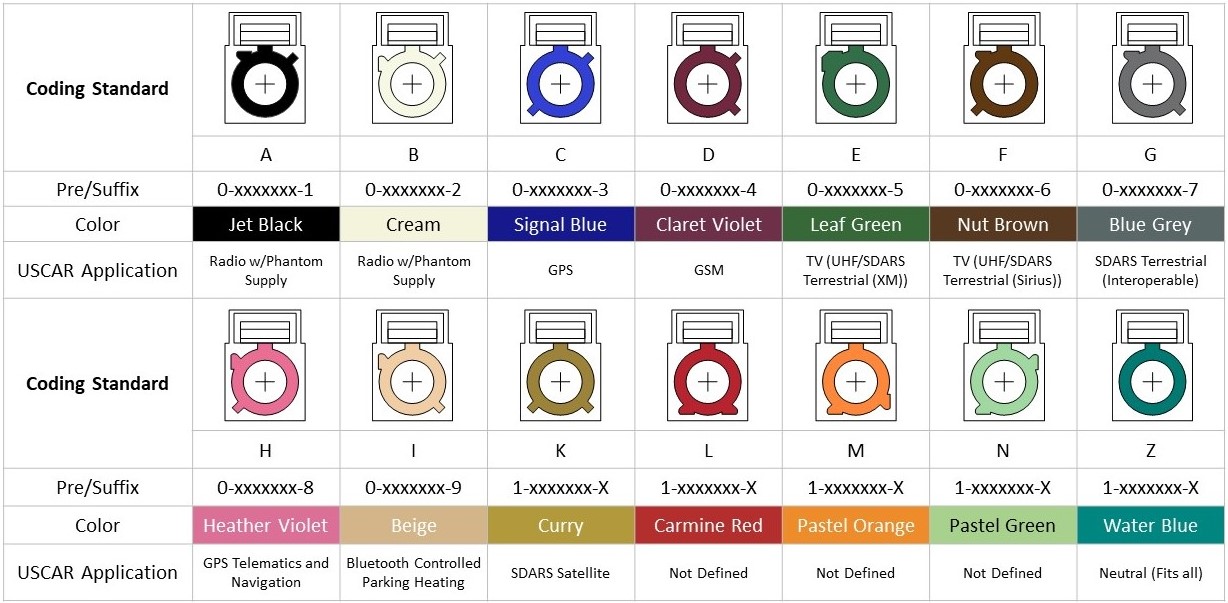

Fakra connectors use a standardized color and coding system to differentiate between different frequencies and functions and are widely used in the automotive industry. The following are common Fakra connector codes.

Fakra A Connectors: Typically used in AM/FM radios and radio communication systems. They are usually coded in black and are used for signal transmission in the low frequency range.

Fakra B connectors: Used in wireless communication systems such as Bluetooth and cell phones. They are usually coded in blue and are used for signal transmission in the medium frequency range.

Fakra C Connectors: Used in GPS navigation systems. They are usually coded in sky blue and are used for signal transmission in the high frequency range.

Fakra D connectors: Used in wireless communication systems such as satellite radio and digital television. They are usually coded in dark green and are used for signal transmission in the high frequency range.

Fakra E connectors: Used in wireless communication systems such as car phones and satellite phones. They are usually coded in purple and are used for signal transmission in the high frequency range.

Fakra F Connectors: Used for automotive cameras and video signal transmission. They are usually coded in orange and are used for signal transmission in the high frequency range.

Fakra Z connectors: A new member of the Fakra family for high-frequency applications. They have excellent electrical performance and are suitable for applications such as wireless communication systems, radar systems and high speed data transmission.

Each Fakra connector has a unique profile and construction to ensure proper connection and signal transmission. They feature a quick-plug design for easy installation and maintenance.

Fakra Connectors Disadvantages

More specialized: Mainly used in automotive wireless communication systems, so their application is relatively limited. If connectors are needed for other areas or applications, adapters or converters may be required.

Manufacturer Dependency: Different vehicle manufacturers may have different specifications and coding for Fakra connectors, which may result in incompatible or non-interoperable connectors between different vehicle models.

Size Limitations: Due to limited space in automobiles, fakra connectors are often small in size. This can present some challenges to maneuverability during installation and maintenance, especially for those with larger fingers or limited vision.