Automotive Connectors Basic and Development Trends Overview

Introduction

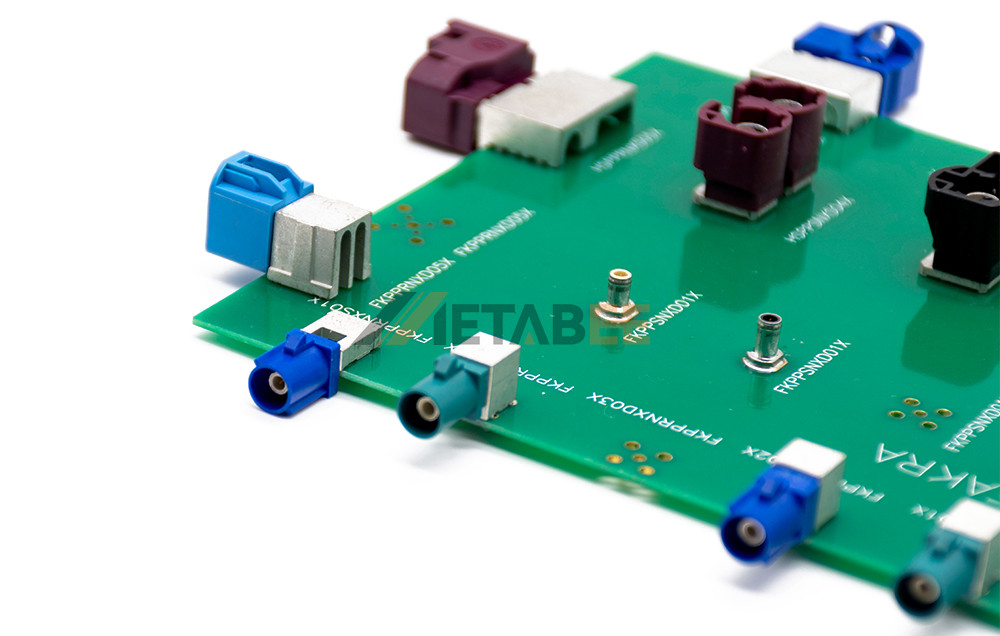

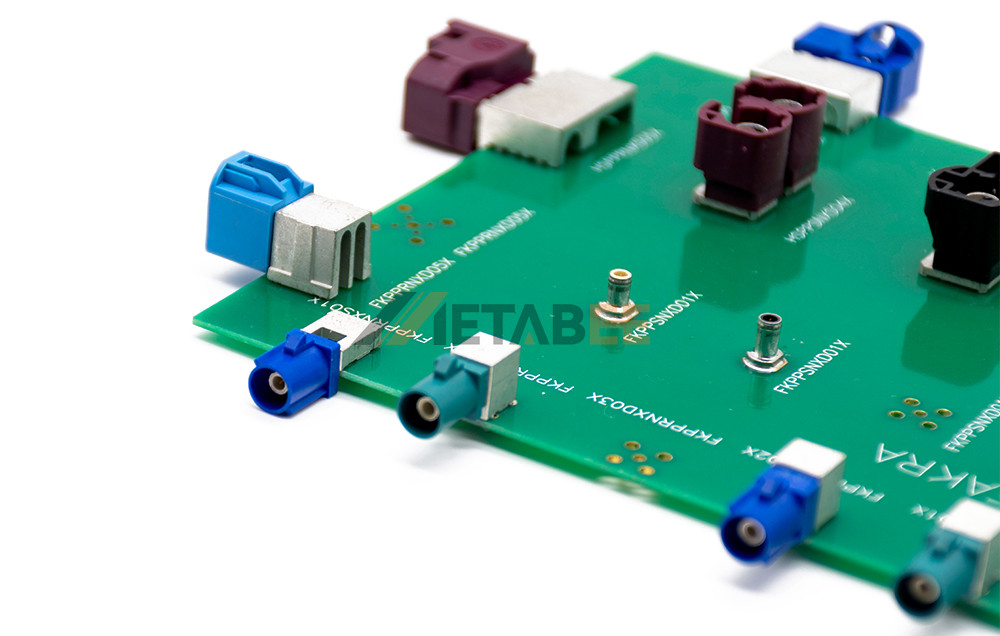

The automotive connector is a very common component for electronic engineers and technicians. Its role is simple: to build a bridge of communication between blocked or isolated circuits in an electrical circuit, so that current flows and the circuit realizes its intended function. Automotive connectors are constantly changing in form and structure. They consist mainly of four basic structural components, namely: contacts, shell (depending on the type), insulator, and accessories.

There are nearly 100 types of connectors used in general automobiles, and hundreds of connectors used in individual models. As people's requirements for automobile safety, environmental protection, comfort and intelligence are getting higher and higher, the application of automobile electronic products is increasing, which makes the number of automobile connector applications continue to increase.

Basic Structure

The four basic structural components of the automotive connector, it is these four basic structural components, so that the automotive connector can play the role of a bridge, so that the stable operation of the car.

First of all, the contact piece is the core component of the automotive connector to fulfill the function of electrical connection. Usually, the contact pair consists of a male contact piece and a female contact piece, because the electrical connection is accomplished through the insertion of the two parts.

Male contacts are rigid parts with cylindrical (round pin), square (square pin) or flat (insert) shapes. Male contacts are usually made of brass and phosphor bronze.

The female contact piece is the jack and is the key part of the contact pair. It relies on the elastic structure inserted into the pin when the elastic deformation generated by the elastic force and the male contact piece to form a close contact to complete the connection.

Jack structure in a variety of forms, there are cylindrical (sub-slot, indentation), tuning fork type, cantilever beam type (longitudinal slots), folding type (longitudinal slots), box type (square jacks) and hyperbolic line spring jacks and so on .

Second, the shell, is the shell of the automotive connector. It secures the connector to the device by providing mechanical protection for the built-in insulated mounting plate and pins, and by providing alignment when plugs and sockets are inserted.

Third, the insulator, also commonly referred to as the automotive connector base or insert. Its function is to align the contacts in the desired position and spacing and to ensure insulation from the shell. Good insulation resistance, voltage resistance and easy processing is the basic requirements for the selection of insulating materials processed into insulators.

Fourth, accessories, divided into structural parts and installation parts. Structural fittings such as retaining rings, locating keys, locating pins, guide pins, coupling rings, cable clamps, seals, gaskets and so on. Installation fittings such as screws, nuts, spring rings and so on. Most of the fittings are standard and common parts.

Design Standards

With the rapid development of the automobile industry, various functional parts and various components on the automobile continue to develop in the direction of intelligence, refinement and reliability. It also puts forward the structural design, appearance design and material of automobile connectors. Higher requirements. Automotive connectors must comply with the USCAR-20 standard, which is a performance standard for automotive electrical connector systems. It is necessary to specify that the electrical connector contact surface of the automotive connector should always be reliable throughout the life cycle, including the following factors:

1) Stable and reliable connector contact material.

2) Positive force stability.

3) Circuit voltage and current stability.

4) Temperature requirements within specified limits, including ambient temperature and its own temperature rise.

5) Better robustness.

6) Must be the same as the connector used in high-speed, long-distance communication computers, automotive connectors must be able to work reliably in harsh conditions.

7) Connector insertion force: 20.5kg or less

8) Connector retention force: 2.5kg or more

9) Heat resistance: -40~120°C

Automotive Connector Development Trend

Connector products "miniaturization", "high-speed", "intelligent" is the trend of future development. The industry's future technological innovation is mainly focused on the following directions:

(1) Miniaturization

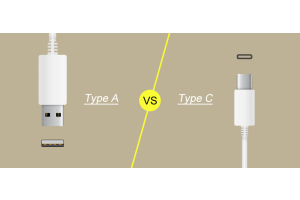

The technology is mainly for the connector miniaturization trend and development, can be applied to 0.3mm below the ultra-small connector, belongs to the MINI USB series of new varieties. Can be used for multi-contact expansion card slot connector, can meet and exceed the strict requirements of multi-contact surface mount technology butt coplanarity, high precision, low cost.

(2) Wireless Transmission

Connector technology of high-frequency high-speed wireless transmission mainly for a variety of wireless devices communication applications, a wide range of applications.

(3) Simulation Application Technology

It is based on a variety of disciplines and theories, to the computer and its corresponding software such as AutoCAD, Pro / E program stress analysis software as a tool, through the establishment of the product model and the corresponding boundary conditions, its mechanical, electrical, high-frequency simulation and analysis and confirmation of other properties, thereby reducing the cost of product development failure due to material selection, structural irrationality, and other factors, and to improve the development of the success rate. Helps to provide support for the realization of complex system applications.

(4) Connector Intelligent Technology

This technology is mainly applied to DC series power connector products. Intelligent signal detection can be carried out before power delivery to ensure that the plug is inserted into place after the positive and negative poles conductive, connected to the power supply. In the future, due to conductive contact caused by arc damage, burn screen and other adverse consequences, companies need to develop similar intelligent technology for other products.

(5) Precision Connector Technology

Precision connector involves product design, process technology and quality control technology and other aspects. The main technologies include the following aspects:

A. Precision mold processing technology: the use of CAD, CAM and other technologies, the introduction of high-precision processing equipment in the industry, the use of personnel production experience and advanced equipment and technical means to achieve high-precision and high-quality mold products.

B. Precision stamping and injection molding technology: realize precise, efficient and stable all-round control and perfect surface quality of all kinds of stamping parts and injection molding parts to ensure product quality.

C. Automated assembly technology: through the application of precision control technology, semi-automatic testing machine technology, etc., to overcome the problem of manual operation of precision products and improve the core competitiveness.

(6) Manufacturing Process Research

The competitiveness of products depends on the level of manufacturing technology to a certain extent. Continuous development of new manufacturing process and improvement of existing production and processing technology can greatly improve the manufacturing efficiency and quality assurance ability of products.

A. Fine manufacturing process: the process is mainly for small pitch, thin thickness and other technologies. Some companies have conducted research on the process of connectors with a pitch of less than 0.4mm. Such technology can ensure that the company can reach the advanced level of international industry in the field of ultra-fine manufacturing.

B. Light source signal and electromechanical structure integration development technology. It can be applied to audio connectors placed in electronic components. By adding IC, LED and other electronic components to the audio connector, it can also realize the function of transmitting analog and digital signals. It breaks through the current design of audio connector to conduct transmission in the form of mechanical contact.

C. Low temperature and low pressure molding process technology. Utilizing the sealing and physicochemical properties of hot melt materials to achieve the function of insulation and temperature resistance. The encapsulated wire protects the soldering point from being pulled by external forces, and the encapsulation of the DC connector body and the wire has the functions of insulation, temperature resistance, impact resistance, etc., which ensures the quality and reliability of the product and will continue to The future will be developed and applied in different products.