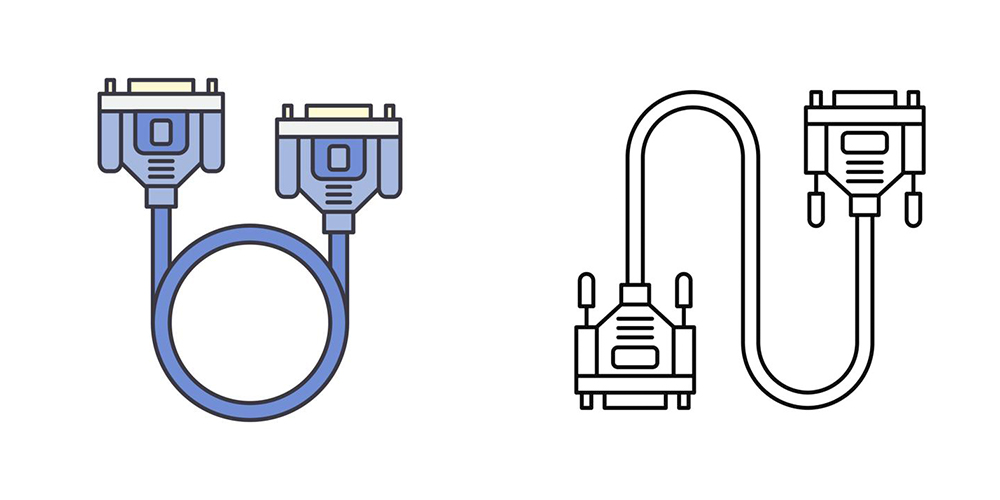

D-Sub Connector: Versatile Connection

The D-subminiature connector, also known as D-sub, is a connector named for its metal housing shaped like the letter D. The connector is used in a wide range of applications, from small consumer products to satellite equipment. This ubiquitous connector is used in a wide range of applications from small consumer products to large satellite equipment.

D-sub connectors

D-sub connectors consist of two or more parallel rows of terminals surrounded by a highly characteristic D-shaped metal shell. This metal shell not only provides mechanical structural support, but also functions as a shield against electromagnetic interference. There are several ways to connect the system circuitry to the terminals on a D-sub connector, including crimping, solder cups, PCB soldering, PCB press-in, and wire-wrap connections. In many cases, connectors are also equipped with a locking system to ensure that they remain connected when subjected to shock and vibration. The relevant models are DB9, DB15, DB25, DB37 and DB50, where the number refers to the number of terminal cores of the connector.

Features

The characteristics of the D-sub connector include the following elements:

- High Reliability: The use of metal socket and plug contact has high reliability and is widely used in industrial automation control systems, test equipment and other fields.

- Easy to Install: Simple installation, easy wiring, and the ability to quickly connect/disconnect, ideal for use in test instruments, measuring instruments and other sites that do not involve connector removal.

- Abundant Specifications: The size and socket arrangement are rich in specifications and various forms, which are suitable for a variety of applications, such as: 9-pin D-sub connector for serial communication; 25-pin D-sub connector for parallel communication; 15-pin D-sub connector for video and display.

- Strong Corrosion Resistance: The metal shell is usually tin-plated and other treatments, strong corrosion resistance.

- Excellent EMI/RFI Immunity: Excellent electromagnetic shielding performance, can effectively prevent external noise and interference, better guarantee the stability and reliability of the equipment.

- Convenient Maintenance: The material is metal, low cost, so easy to replace, convenient maintenance.

With rich specifications and good flexibility, D-sub connectors are suitable for a variety of industry sectors, including computers, audio/video equipment, industrial automation equipment and instrumentation.

Drawbacks

- Larger Size: : Compared to other types of connectors, larger size, as space is limited, may lack of flexibility and reliability.

- Requirement of a Solid Connection Body: Closely related to the solidity of the connection body, if the connection surface is loose leading to poor contact, may affect its electrical performance.

- High Welding Process Requirements: The production of D-sub connectors need to carry out certain processing and welding process, so the production process requirements are relatively high.

In short, D-sub connectors have many advantages, high reliability, wide range of applications, easy to install and maintain, but there are also shortcomings, such as the larger size, the requirement of a solid connection body, production process requirements and so on.

Applications

D-sub connectors are used in a wide variety of electronic products. These connectors are commonly used in communication ports to establish connections between different products such as computers, printers and power supply units. DB9 connectors are used in Token Ring networks and Controller Area Networks (CAN), and D-sub connectors are also used in computer video outputs, game controller ports, multi-frequency analog signals, and AES digital audio recording studios. The use of connectors have changed over time as technology has advanced. For example, early Apple computers used connectors to connect external floppy disks, and Commodore's Amiga computers used connectors to connect external floppy disks along with video output. However, due to the size and cost of these connectors, the D-sub connector has been retired from consumer products. However, these connectors are still active in the non-consumer sector, and continue to offer their end-users significant combined value in terms of form factor, size, density and cost.