M8 M12 Connectors: The Best Choice for Harsh Environments

Modern industry, characterized by outdoor facilities and equipment, relies on resilient and reliable electronic connectors to facilitate good communication between equipment and operators in harsh environments. Industries such as agriculture, food and beverage processing, transportation, and energy have advanced equipment, vehicles, and equipment that are exposed to changing weather conditions and the risk of entry of various contaminants. Circular M12 and M8 connectors meet the needs of harsh and remote environments for data transmission, and they are common industrial electronic connectors. These electronic connectors prevent the ingress of contaminants and withstand extreme temperature, shock and vibration, and pressure conditions while providing reliable signal transmission.

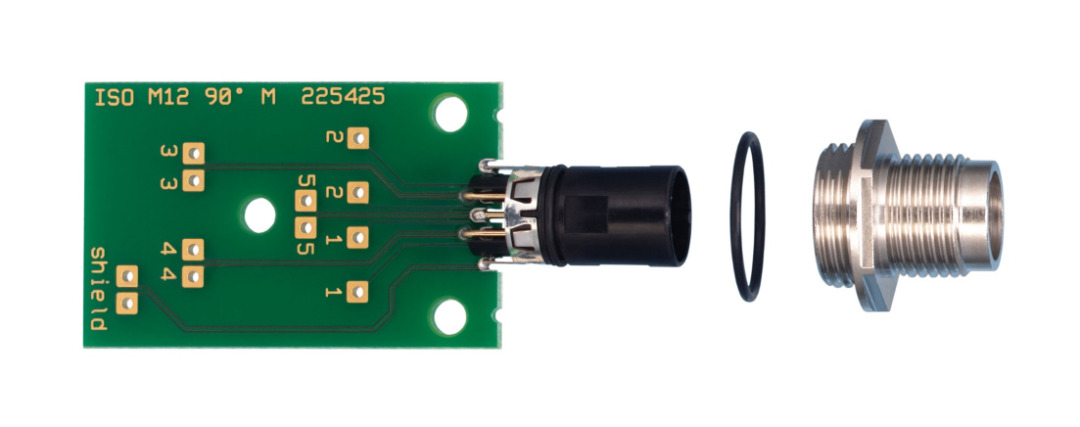

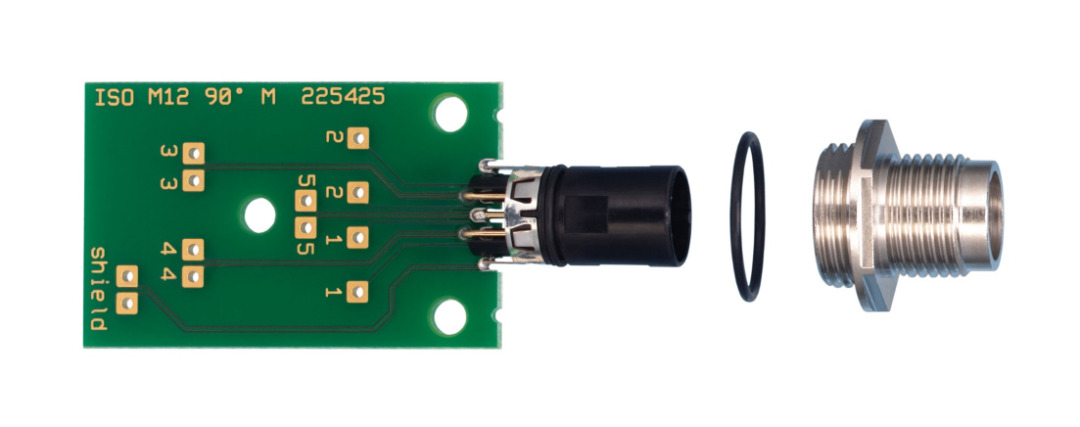

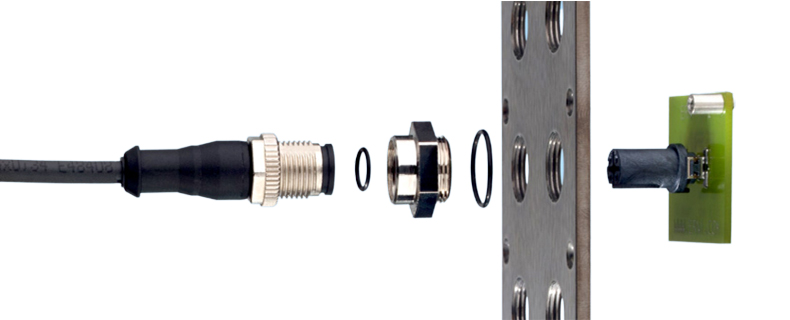

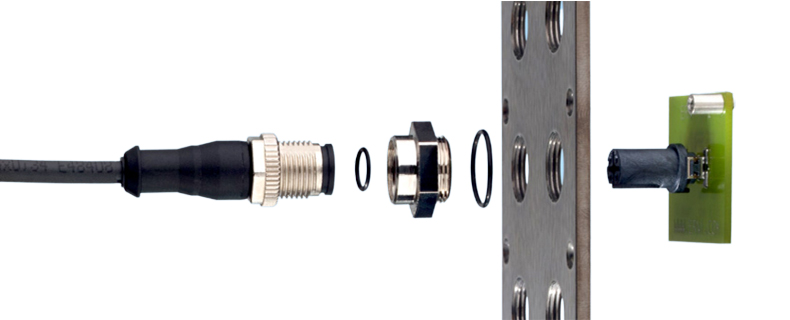

M8 and M12 circular connectors with various codes and accessories, including protective caps and O-ring seals, are available for almost all Fieldbus specifications.

What is M8/M12 Connector?

M8 connectors and M12 connectors are the most commonly used industrial sensing connectors today. To meet the application requirements of small sensors, there are also M5 connectors, M12 connector thread is M12 * 1, M8 connector thread is M8 * 1, the connection method is screw connection, the shell protection level is IP67, with or without cable, the cable can be PVC (ordinary) or PUR (oil and wear-resistant) material, cable length can be according to the user.

The cable can be made of PVC (common) or PUR (oil and abrasion resistant), and the cable length can be customized according to the user's requirements.

The M8/M12 sensing connector has a round shape and a housing made of metal or plastic with excellent water resistance. Sensing connectors (M8/M12) are nowadays recommended for almost all Fieldbus specifications and are traditionally used to connect sensors and actuators in automation technology according to IEC 61076-2-101/104 in accordance with IP67 protection class.

M8/M12 sensing connectors are threaded and locked, designed to be waterproof (IP67, IP68), oil resistant, efficient and stable, and suitable for complex and harsh environments.

M8/M12 Functional Applications in Harsh Environments

Data Transfer Function

M12 connectors have long provided reliable signal transmission for homes and offices. With automation and increasing connectivity, the introduction of Industry 4.0, Industrial Ethernet, and more has created new growth in demand.

D-coded M12 products with Ethernet transmission rates up to 100Mb/s are now being replaced by X-coded M12 products capable of 1GB/s Ethernet transmission rates. In manufacturing environments, X-coded M12 connectors are better suited to handle factory noise, process demands, and harsher environments and are even more responsive to data processing on the factory floor. In addition to manufacturing, X-coded M12 connectors can be used in applications such as IP cameras, agricultural equipment, public transportation, rail infrastructure, and broadcast systems.

Remote Transmission of Signals

Industrial activities are not limited to the scope of manufacturing but also include vehicles and facilities in remote locations such as agriculture, forestry, and energy sites. Most of this exploration requires sensors capable of monitoring different temperatures, pressure, humidity, and vibration conditions.

Comparative tracking index (CTI) of 600 angle M12 connectors can be insulated with these harsh environment applications, in these harsh environment applications can match the sensor and other components. Engineers can also choose to add shielding and O-rings to achieve an IP65/67 M12 connector solution. When these connectors are mated and locked, they reliably transmit signals under harsh environmental conditions.

Eliminate Dust and Debris

Connectors used in heavy equipment and agricultural applications must be resistant to water, dust, sand, and chemicals and able to operate under extreme temperature, vibration, and pressure conditions. That's why rugged construction and materials are critical to ensure reliable signal transmission under harsh environmental conditions.

M8/M12 connectors range in IP ratings from IP67 (i.e., fully dustproof with water protection for up to 30 minutes at depths of up to one meter) to IP69K (i.e., products proven to withstand sanitary washdown conditions reliably) and feature a broad combination of pin counts, shielding, termination, and coding to meet mining, agricultural, earth moving and other harsh environment application scenarios while providing on-board or remote operators with personnel with high-quality signals.

M12 connectors with O-rings provide rugged protection from debris and water in harsh environments with increasing data demands

The difference between M8 and M12 connectors

The difference between the M8 connector and M12 connector is that the sizes of the two calibres are different. Second, the two threads are different; the M12 connector thread is M12 * 1, while the M8 connector thread is M8 * 1. M8 connector and M12 connector is the same between the two connector method is the same, are screw connections, followed by the same functionality two The M8 connector and the M12 connector are the same in that they have the same connector method, both are screw connections, the second is that they have the same functionality. They both have the options of the elbow and straight and with and without cable.

Summarize

Since entering the market in the mid-1980s, M8/M12 connectors have evolved features and functionality to meet the changing needs of the industry's many harsh environments. Increasing connectivity in all areas of the industry requires high reliability and strong signal integrity from a smaller footprint. Vehicles are becoming part of the Internet of Things, increasingly demanding highly reliable connectivity. Agriculture and its transportation markets are becoming more high-tech. As we continue to improve efficiency across industries, they are easy to install and modify, making M12 and M8 connectors an effective solution for harsh environment signaling applications.