Robust MIL-SPEC Connectors: Empowering Defense and Industrial Applications

Connectors required for military/defense equipment, particularly those providing interfaces for input and output (I/O) devices, must adhere to strict quality and safety standards, many of which were initially defined by the US Department of Defense. These connectors often involve numerous technical terms, making them occasionally challenging to comprehend. Connectors that comply with these standards are commonly referred to as military standards, MIL-STD, or MIL-SPEC connectors.

Such connectors are designed to operate reliably in harsh environments such as military vehicles, aircraft, naval vessels, and mobile devices. They are specifically engineered for durability and can withstand the impact of vibrations, corrosion, dust, water, and other environmental factors. Connectors meeting these stringent requirements are now also widely used in commercial sectors such as security, renewable energy, industrial applications, and oil and gas industries. By adopting standardized specifications, connectors provide manufacturers with a common set of features and performance, facilitating system integration and enabling the identification of spare parts suitable for field maintenance and repair.

MIL-DTL-5015

The MIL-DTL-5015 connector, previously known as MIL-C-5015, is one of the earliest circular connectors used in military applications. They are medium-density, environmentally resistant connectors that utilize fixed solder and PCB contacts, as well as detachable crimp contacts, operating within a temperature range of -55°C to +125°C. This standard defines a threaded coupling mechanism and has spawned a popular product line with the same materials and contact arrangement, offering secure and quick reverse bayonet coupling.

The MIL-DTL-5015 connector features a circular shell and socket, providing reliable electrical connections and mechanical protection. Its threaded coupling mechanism enables stable operation in harsh environmental conditions. These connectors are often characterized by features such as waterproofing, shock resistance, and vibration resistance, making them widely used in military aviation, naval, vehicular, and industrial equipment applications.

MIL-DTL-5015 connectors are commonly used for transmitting various types of electrical signals, including power, signals, and data. They offer a range of socket and lead configurations to meet different application requirements. Additionally, accessories such as protective covers, backshells, and seals can be added to MIL-DTL-5015 connectors to provide additional protection and environmental sealing.

MIL-DTL-38999

The MIL-DTL-38999 connector, previously known as MIL-C-38999, is a product line consisting of four types of connectors. These connectors feature bayonet, threaded, or Breech Lok coupling mechanisms, offering high density, quick connection, and environmental resistance. They employ removable contacts and can operate within a working temperature range of -65°C to +200°C. Today, they are among the most popular series of circular connectors for high-performance applications.

- Series I connectors are anti-rotation and utilize a Bayonet coupling. They are suitable for blind mating systems or other challenging mating areas where fast disconnect is required.

- Series II connectors are low-profile versions of the Series I. Being low-profile means they do not have anti-rotation features, but they are highly favored in situations where weight or space is limited.

- Series III connectors employ a quick three-start Threaded coupling with anti-rotation capability, making them the most common military circular connectors. They are suitable for blind mating areas, exhibit excellent vibration resistance in high-temperature environments, and can be used in damp conditions with appropriate connector accessories.

- Series IV connectors use the Breech Lok mechanism for coupling, offering anti-rotation features. They are lightweight, well-suited for blind mating applications, and provide good vibration resistance.

MIL-DTL-26482

The MIL-DTL-26482 connector, previously known as MIL-C-26482, is a space-saving bayonet lock connector. Connectors and accessories that comply with this standard are designed to provide quick disconnect capability in harsh environments. They feature high density, fast connection, and environmental resistance. They employ solder and PCB fixed contacts, as well as detachable crimp contacts, and can operate within a working temperature range of -55°C to +125°C. These connectors are widely used in various applications and industries, offering cost-effective solutions.

- Series I connectors provide solder contacts and possess anti-rotation and bayonet coupling features.

- Series II connectors offer detachable crimp contacts and are compatible with similar connectors in the Series I.

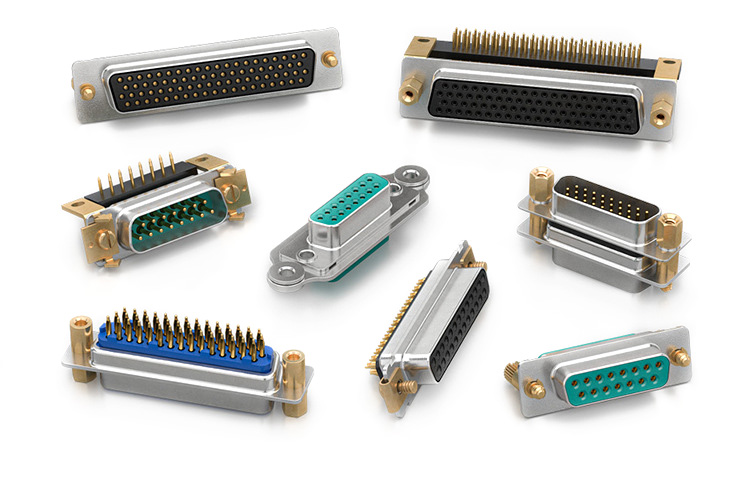

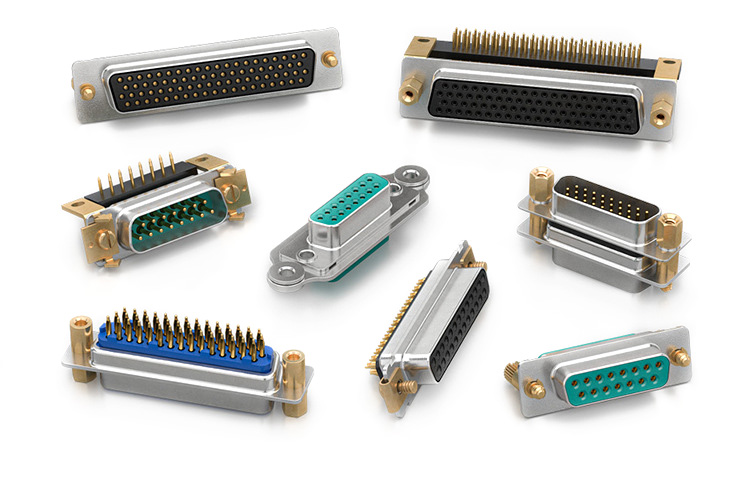

MIL-DTL-24308

Previously known as MIL-C-24308, MIL-DTL-24308 represents non-environmental, polarized shell, rack and panel, and microminiature connectors. They come with pin and socket, solder (non-removable), insulation displacement (non-removable), or crimp (removable) floating or rigid mounting brackets. Their operating temperature range is from -55°C to 125°C.

Also referred to as D-subminiature or D-sub connectors, they are perhaps the most commonly specified connector style in electronic devices. They are used in environments where weight and space considerations are important, while still accommodating a significant number of circuits relative to their size. As such, they are an ideal choice for military equipment such as missile controls, aircraft and ground support systems, as well as satellite, video, and communication devices. In addition to rack and panel applications, these products can also be adapted for cable use by employing backshells, strain relief clamps, and other related accessories.

They are designed for military applications: G and N classes for environments ranging from -55°C to 125°C (N class for environments requiring low residual magnetism), H class (hermetic) for maintaining pressure/vacuum in the box/container where the connector is mounted, and D, K, and M classes for high-reliability space applications.

MIL-DTL-83513

Previously known as MIL-C-83513, MIL-DTL-83513 specifies micro, polarized shell rectangular connectors with solder or non-removable crimp contacts. They are rugged and durable, intended for use in harsh environments, and feature high dielectric strength, high current capacity, low contact resistance, and high resistance to vibration and shock. They are lightweight, compact, and offer high-density contacts on a 0.050-inch grid or pitch basis.

They are also known as Micro-D connectors and are commonly used in applications such as radar, shoulder-launched weapons, military GPS, medical devices, satellites, drilling tools, advanced soldier technology, and aerospace electronics.

Derived products with similar dimensions but with metric 2-millimeter or smaller contact spacing are becoming increasingly popular in similar applications. These connector styles typically offer higher contact density with similar electrical and mechanical performance as specified in MIL-DTL-83513, and many also provide additional benefits such as removable crimp contacts.

To address the need for minimizing space and weight without sacrificing performance, the MIL-DTL-28748 specification provides designers with the standards for heavy-duty rectangular connectors. MIL-DTL-28748 ensures the use of high-quality materials, resistance to impact and vibration, positive locking, and long service life. This specification is commonly employed in aerospace, instrumentation, and various types of portable devices. Previously known as M28748, the MIL-DTL-28748 product series includes high-density and standard-density rectangular connectors with non-removable solder contacts and removable crimp contacts.

Summary

The vast array of military connector specifications in the electronic connector industry can be overwhelming at first. However, understanding these specifications is crucial for selecting the right connector to meet the specific requirements of military, aerospace, and industrial applications.

As technology continues to advance, military connector specifications evolve to meet the increasing demands of modern applications. Staying updated with the latest developments in connector standards and exploring emerging technologies will enable us to harness the full potential of these connectors in our designs.